Analysis: The environmental impact of Flaus versus floss

As a Product Design Engineer with a focus in consumer electronics, I love keeping up with the latest devices. I’m also a skeptic of all things “green,” knowing the term is often exploited as a marketing tactic to make a product more appealing. See my previous article on greenwashing, and whether new tech can avoid sacrificing the environment.

When I learned about Flaus — a device designed to make the habit of flossing easier, while reducing plastic waste — I was immediately curious. The device claims to use 95% less floss, is made with recyclable plastic, and was featured on Shark Tank. The Flaus website is flashy and modern, and they mail you replacement flossers when you need them. I found it hard to imagine a scenario in which this new electric flosser could somehow have less of an environmental impact than traditional flossing methods, so I decided to buy one and see for myself.

We’ll take this in a few steps. First, tear down the Flaus device and get a read on the materials used and the recyclability of all the components. For products that claim to be good for the environment, it’s important to look at the end-to-end experience, from packaging to disassembly for recycling.

Next, we’ll look at the competition for this flosser — namely floss picks and traditional floss on a roll. Disposable floss picks can’t be great for the planet since we’re tossing out plastic each time we use them. Floss rolls have tons of empty space and a plastic housing around them that’s also discarded. Is there a clear winner on environmental impact?

Dissecting the packaging

First up, let’s look at the product packaging and “unboxing experience.” Product packaging is a fascinating balance of cost, quality, appearance, and recyclability. It’s typically your customer’s first impression of the product, but also something that’s thrown away almost immediately. Lately, we’ve seen a bigger push toward packaging minimalism and environmentally friendly designs like using paper pulp trays instead of plastics. Let’s see how Flaus does here.

Two words came to mind immediately when the box arrived: excessive and trendy. This thing checks most of the millennial branding trends: cool fonts, bright colors, fun phrases, and vibes. The packaging is complicated, with flaps on flaps and small boxes with parts inside. Kudos to the packaging designer for embossing braille in various locations — this was a very cool touch (literally). The use of foil tapes and multiple boxes, though, may make it harder for someone with limited vision to actually unbox the device.

Let’s weigh everything included and see some fun numbers:

- Mailer box: 81 grams

- Flaus device with head: 60 grams

- Flaus replacement heads: 45 grams

- Charging cable: 14 grams

- Wireless charger: 41 grams

- Packaging: 122 grams

There’s a lot of packaging material here. To put it in perspective, the entire Flaus in box weighs 363 grams, so with 122 grams of packaging, we’re talking about one-third the total weight in just paper. This is excessive. Another fun thing to keep in mind is that traditional markups for direct-to-consumer devices range from three to seven times the cost of goods sold. I wouldn’t be surprised if this packaging costs upwards of $4/unit, meaning a customer could be paying anywhere from $12 to $28 for this unboxing experience.

I also need to call out a big no-no if you’re aiming for environmentally friendly packaging — using foam. Below you can see a few pieces of polyethylene foam were glued together and used to create a support for the Flaus device. Some districts will recycle this material, but most won’t. In the majority of cases, this goes into a landfill.

Packaging rating:

Vibes: ⭐⭐⭐⭐⭐

Accessibility: ⭐⭐⭐⭐

Environmental Impact:: ⭐⭐

First impressions of the Flaus device

Included in the box are a Flaus unit, a wireless charging stand, a bag of 45 Flaus refill heads, and a USB cable. Let me get this out of the way first: This device feels great! It’s wrapped in rubber material (TPU or silicone, hard to tell) and has a nice ergonomic design that makes it easy to get a good flossing (Flausing?) session in. The charger is very lightweight, and the device seems a bit prone to falling off when docked. It’s less sturdy than your average electric toothbrush, but good enough. It feels like there may be some magnets helping to position the Flaus device on the charger, but they’re fairly weak.

Unfortunately, my praise ends here. The Flaus device vibrates at three speeds, and none of them feel like they’re doing anything to help floss better or remove additional plaque. The highest speed tickles my brain and ears a bit, which is fun but not productive. The Flaus head was nicely shaped and attached to the handle with a solid click, but I broke the floss on two of them in a single session. This is about on par with my experience with typical floss picks. Replacing the heads multiple times in a session is a bit tedious and the waste begins to pile up quickly. Flaus has a program to help recycle the used heads, provided that you clean them and fill out a form online to obtain a shipping label to mail them back to a facility. We’ll dig into that later.

Being an inquisitive mechanical engineer with a calendar blocked off from meetings, I began to tear down the device to learn its secrets.

Charger discoveries

Let’s start with the charger. I immediately knew I was in for trouble when I started looking for a way into the charger. The charger has a rubber foot around the bottom of the device, which typically hides a few thread-forming screws that hold the casing together. Not today!

After feeling foolish, I tried prying the two halves apart, but I was making very little progress. I ended up using a small arbor press to gently crush the housings, which I later learned was actually helping to break the glue that was holding the two halves together. Finally I was in, seeing a decorative top housing and a white plastic cap over the remainder of the electronics.

Some aggressive prying was required to finally expose the guts of the charger, and I was greeted with a massive amount of potting compound. This is essentially liquid plastic that cures and forms a solid block around the electronics. You can see a cute little wireless charging coil in the center, and the USB-C port on the bottom of the image below.

Unfortunately, my progress was slowed from here, as the potting compound was very difficult to remove. My guess is that this device had a change in requirements during the last few months of development that required it to be more water resistant than it was originally designed for. The easiest way to solve this problem is to fill any open areas with potting compound. The downside is that you can’t break this device up for recycling easily (or at all), and this is essentially just e-waste. I managed to chip away to separate a few magnets and wireless charging circuit board before I got dissuaded and turned to the Flaus device itself.

Inside the Flaus device

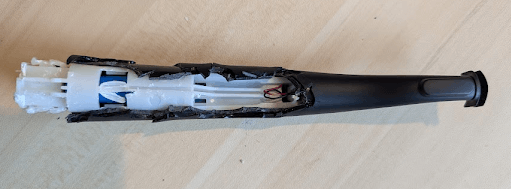

Let’s cut right to the chase here: unless I missed a crucial step, I don’t think it’s possible to take this device apart. It seems to be designed for rapid assembly with zero regard for disassembly or recycling. The bottom cap of the unit came off with gently prying, inspiring confidence that I could easily take this device apart with some coercion. This was where my confidence faded. I broke out my handy snips and flathead and began trimming away the rubber overmold and plastic body to expose a white plastic inner frame.

Fast forward 90 minutes, a Band-Aid, and some moderate curse words later, and I was able to get everything apart. I had a literal pile of snipped housing pieces beside me (which I carefully separated into rubber and plastic pieces for weighing), an electronics frame, and a bottom cap. The vibration motor was adorably small, and the electronics themselves weren’t interesting aside from the charging coil, a few LEDs, a button, a battery, and a microcontroller.

The white plastic frame has some fun snap hooks used to hold onto the PCB, marked with the UL listing of their fab house, E486889, made by Shenzhen Lutongda Technology Co., Ltd. There’s also some more aggressive hooks used to connect to the handle of the Flaus and prevent any rattling. Whoever designed this part had a blast!

While peeling the rubber off the handle, I noticed the “Bite Me” embossed in the plastic. This was very interesting because the rubber covered this logo entirely. It makes me think that an earlier version of the Flaus may not have had a rubber grip around it, or that an engineer had a few extra minutes and felt cheeky. We’ll never know!

From an environmental standpoint, the device scores poorly. Black plastic is notoriously hard to recycle and overmolded plastics are rarely recycled. The electronics required a ton of time to extract from the handle and realistically this is yet another piece of e-waste. This doesn’t have to be the case here, either! Oral-B toothbrushes are waterproof, fairly easy to repair, and cost less than a Flaus.

Let’s break down the total mass of the device by material:

- Electronics (battery, boards, cables, motor): 21 grams

- Plastics and potting compound: 50 grams

- Rubber: 14 grams

- Magnets: 18 grams

Flaus unit rating:

Appearance: ⭐⭐⭐⭐

Experience: ⭐⭐⭐

Environmental Impact:: ⭐

Comparing Flaus vs. floss vs. floss picks

One of the big pitches on the Flaus site is that it’s a more environmentally friendly way to floss. Let’s compare it to the other common methods of flossing and see how it stands up. We have the classic floss dispenser and the disposable plastic floss picks as the main competition. We’ll start with a simple comparison of the plastic used for each.

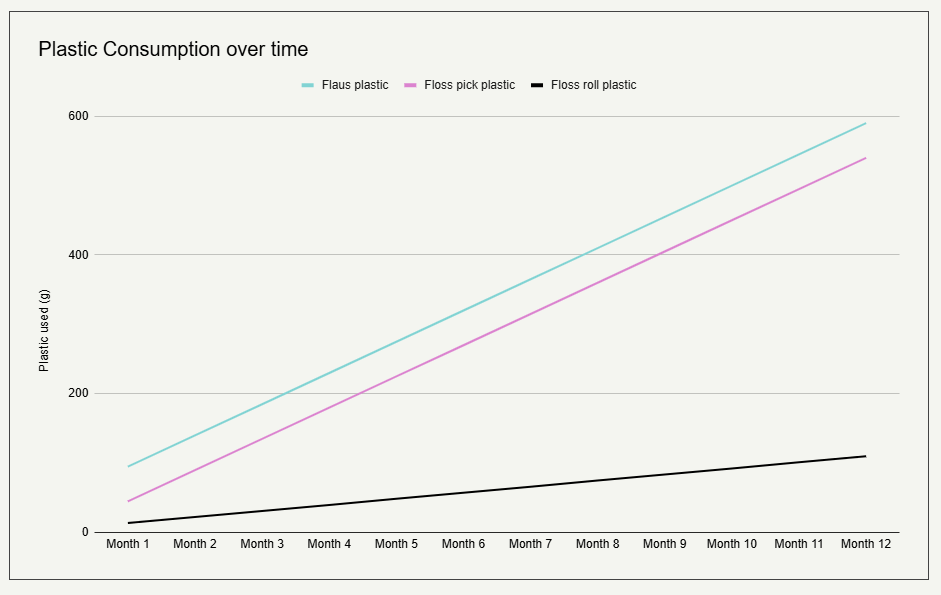

Plastic consumption

The floss dispenser is a classic. A molded polypropylene housing opens up to reveal a plastic frame holding a stamped metal cutter, and a plastic spool with around 5 yards of floss around it. Assuming 8 inches of floss are needed per session, we can safely estimate we need 1.5 floss containers a month. We’re looking at around 5 grams of plastic per case, so we’ll call it 7.5 grams of plastic used monthly.

A floss pick weighs around 1 gram and, as mentioned, requires one or two per session. Let’s call it 45 per month, assuming we get lucky once in a while. We’ll make the same assumption of 45 Flaus heads per month (which, conveniently is how they sell the refill packs!).

The total plastic consumption of a Flaus device starts with the 50 grams from our teardown of the device. Knowing that we’re at the same consumption rate of heads and floss picks, and that they weigh nearly the same, we’re never going to use less plastic here. Meanwhile, our classic spool of floss is actually doing a great job here!

We can then dig in deeper and attempt to factor in the recycled plastic floss heads into the equation. If we’re good consumers and return each and every floss head we use, and if the Flaus heads are made of some amount of recycled plastic (let’s assume 30%, which is actually pretty high for most molded parts), our graph looks a bit different.

With these assumptions factored in, Flaus begins to use less plastic than disposable picks around 2.5 months in, but never uses less floss than a traditional roll. Plastic consumption is just one way of comparing the devices. Let’s also look at the carbon footprint of each option as well.

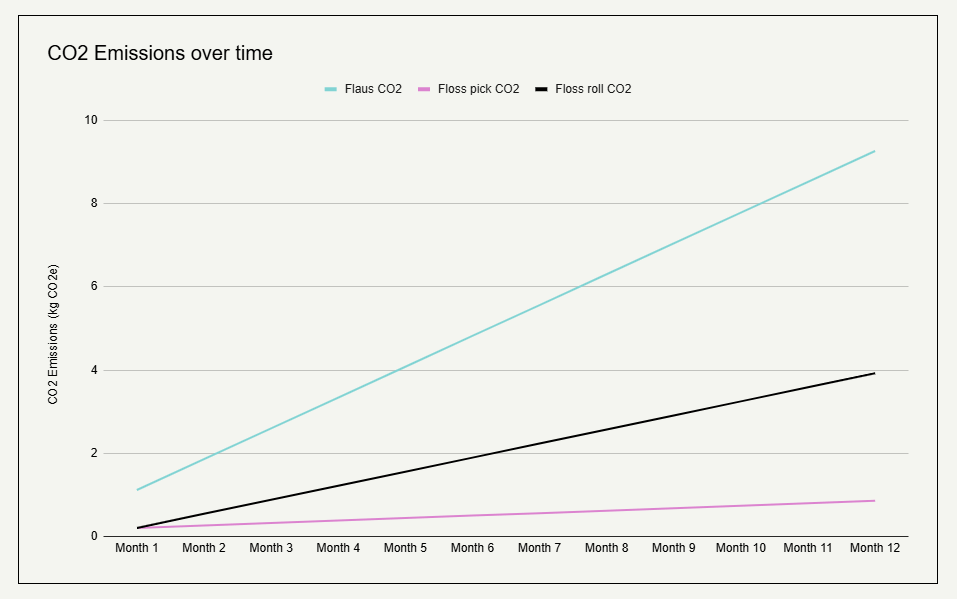

Carbon footprint

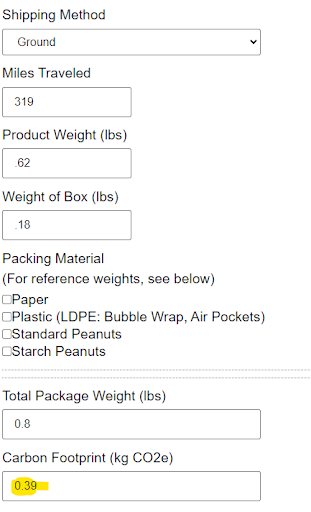

Calculating this will be messier than merely measuring plastic mass and doing some math. Thankfully, smarter people than me exist (everywhere!) and they created this awesome calculator. Let’s use my actual order information and calculate the carbon footprint of the Flaus device shipped to me.

And 0.38 kg of CO2e are used to ship this Flaus from New Jersey to my door in Vermont. Neat! Let’s now assume every month I’m mailing back my used Flaus heads and receiving new ones. This is about 0.37 kg of CO2e each way.

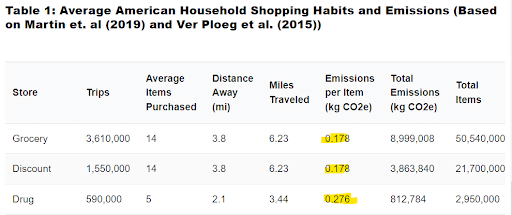

We can also assume I’m purchasing a 5-yard spool of regular floss and a pack of 160 floss picks at my local store. Using the handy chart on the above calculator, we can see that each trip uses an average of 0.21 kg of CO2e per item.

Let’s graph these and compare! With an initial investment of 0.38 kg of CO2e, plus a recurring 0.37 kg of CO2e every month for the Flaus, we’re already starting with a hefty impact. Interestingly, the bulk pack of flossers seem to have a lower impact than the more-often-replaced flosser roll. This is because we’re picking up these floss picks less often — around every 3.5 months. Meanwhile, we’re grabbing a new floss roll each month.

For simplicity’s sake, I’m purely comparing the costs to acquire more floss here, not the lifetime costs. If we were to get fancier, we could include the costs to replace a Flaus device every few years. This is a slippery slope, and I fear I’ve already lost your attention. For those of you still reading, let’s go deeper.

Environmental impact of injection molding

Using the power of AI, I was able to come up with a simplified formula to calculate the carbon footprint of injection molding. We’re assuming many things here to keep this calculation simple:

- We assume a generic thermoplastic with a production footprint of around 2 kg of CO2 equivalent per kg of plastic.

- We assume our factory is using somewhat newer machinery but not the most energy efficient models out there.

- We know we’re looking at simple plastic parts, which reduce the energy usage for molding. We can assume 0.5 kg of CO2 equivalent per kg of plastic.

Our simplified equation looks like this:

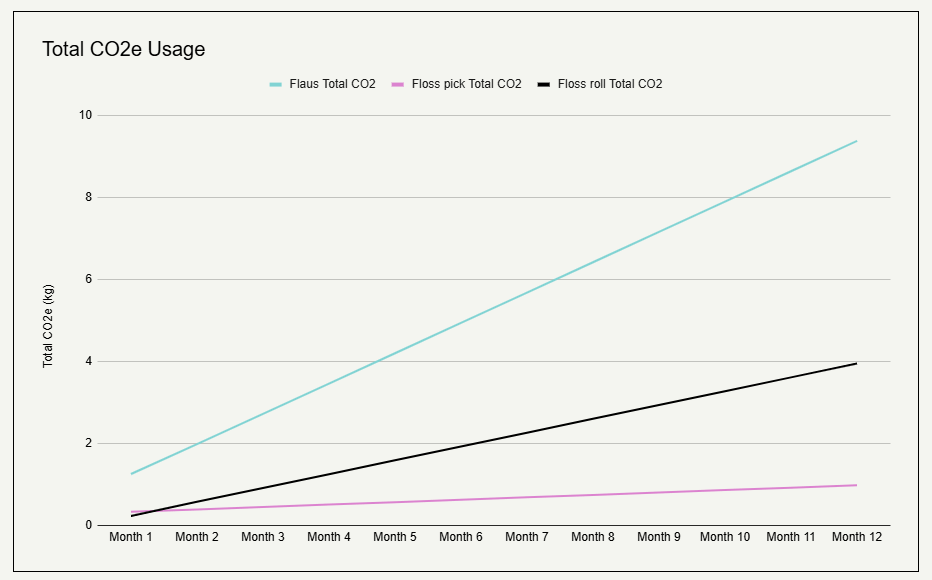

Applying this to our three competitors, we can compare the environmental impact of each option. Let’s factor these into the previous comparison, where we looked at the trips required to get new floss.

In conclusion

The main conclusion from this analysis is that there’s no scenario in which using a Flaus device is actually net beneficial to the planet compared to using floss picks or floss rolls.

I think the Flaus device is a beautifully designed piece of hardware with an unknown improvement on the actual flossing performance compared to the competition. It may be the constant reminder folks need to keep up a flossing ritual, and it may be a better experience than rolls or picks. I have no qualms with products being sold to make a day-to-day experience better for the user! I am, however, ready to do unnecessary amounts of math to disprove when a product claims to be better for the environment.

A sad truth about designing products is that sometimes it may actually be better for the planet if you don’t make anything new at all.

informal is a freelance collective for the most talented independent professionals in hardware and hardtech. Whether you’re looking for a single contractor, a full-time employee, or an entire team of professionals to work on everything from product development to go-to-market, informal has the perfect collection of people for the job.

`