Textiles are the overlooked powerhouse in your product toolkit

When you think about innovation in medical science, textiles might not be the first material that comes to mind. But take it from a completely unbiased soft goods engineer: They should be. From smart fabrics that sense biological signals to implantable scaffolds that regenerate tissue, textiles are quietly driving some of the most exciting breakthroughs in healthcare. This post explores how textiles function far beyond bandages and scrubs — and why you should rethink how you approach soft goods development.

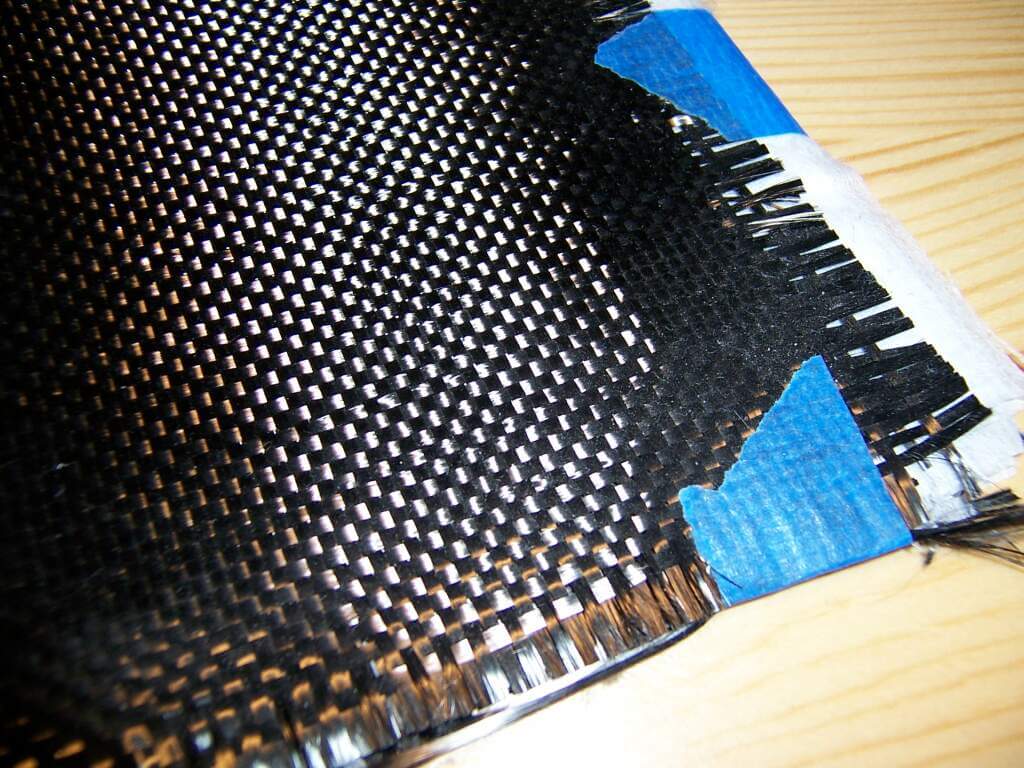

If textiles are this critical in medicine, where else are they hiding? Spoiler: almost everywhere. This goes beyond medtech — the underuse and misuse of textiles is seen across industries. You’re likely already relying on textiles more than you realize and are missing opportunities to harness their properties. But you’re in good company, most teams do. Next time you’re on a plane, stop to appreciate the carbon-fiber textiles in the wings — light enough to keep the aircraft efficient, strong enough to stay impenetrable even to The Twilight Zone’s strongest of gremlins.

Woven carbon filaments. Photo by Scott Williams.

Textiles often get overlooked for two big reasons: their ubiquity and long history. We’ve been working with them for millennia, and they’ve blended into the background. They’re in our clothes, beds, cars, shopping bags, wet wipes, tea bags, air filters, and even roofing underlayment. Once you start spotting them, you’ll never look back. Let’s take a second look at one of the most underappreciated tools in your product development kit.

What is a textile and why that matters

The word “textile” is typically associated with clothing, but it’s any flexible material made from fibers or yarns, often structured in a repeatable pattern. That includes wovens, knits, nonwovens, braids, meshes, and hybrids.

People default to “fabric” because it’s familiar. We notice our sweater more than the geotextile under the road, or the fiber-reinforced composite in our car. But that narrow mental image is misleading. Textiles are one of the few material categories that span vast industries, like aerospace and healthcare, yet operate on the same underlying design principles; often regardless of intended end-use. A braided ligament graft, a filtration membrane, and a parachute canopy all belong to the same family of engineered structures — though they do tend to awkwardly avoid each other at family reunions.

Fibers can be chosen for their chemistry and performance. Yarns can be designed for stretch, conductivity, or wicking. The construction can control porosity, strength, or even drug release. And surfaces can be treated to repel water, kill bacteria, or change properties in response to temperature. The opportunities are endless when you know where to look.

The functional roles textiles quietly play

In medical applications, textiles serve precise, high-stakes purposes, often falling into three broad functional categories: curative, supportive, and preventative.

Curative: Directly address a medical condition or injury, active role in treatment or repair.

- Implantable scaffolds that encourage tissue regeneration

- Wound dressings that maintain an optimal healing environment

- Drug-delivery garments that release medication over time

Supportive: Aid in patient function during recovery or long-term management, but may not cure the underlying problem.

- Braces and compression garments that stabilize joints and reduce swelling

- Smart gloves that reduce tremors in Parkinson’s patients

- Lumbar supports that redistribute strain to prevent further injury

Preventative: Designed to stop harm before it occurs, protecting the body from injury, infection, or environmental damage.

- Antimicrobial coatings to reduce infection risk

- Mesh reinforcements used in surgical repair to prevent recurrence

- Protective barrier fabrics that shield against pathogens, UV, or chemicals

Applying the same thinking elsewhere

These three categories are specific to medical textiles; however, the approach behind them is universal: Identify the core role a textile plays in solving a problem, then group those roles into functional categories. In sports, that might mean recovery, performance enhancement, and protection. In industrial design, it might mean filtration, insulation, and reinforcement. Focusing on function helps to uncover areas for textile innovation.

Properties that make textiles magic (and undervalued)

Textiles aren’t just “off-the-shelf” materials — they’re systems you can engineer. By adjusting fiber chemistry, yarn geometry, construction, and surface finishes, you can fine-tune performance for almost any use.

Fiber chemistry: The foundation

A fiber’s chemical makeup drives its natural behavior:

- Cellulose (cotton, linen): Breathable, moisture-absorbent, and soft. Biodegradable, strong when wet, and takes finishes well — but highly flammable without treatment

- Protein (wool, silk): Naturally flame-resistant and self-extinguishing, great at regulating heat and moisture, and sometimes antimicrobial. Weaker when wet

- Synthetics (polyester, nylon, acrylic, olefin, elastane): Highly tunable for strength, stretch, abrasion resistance, and moisture control. Resist most chemicals and keep their strength when wet

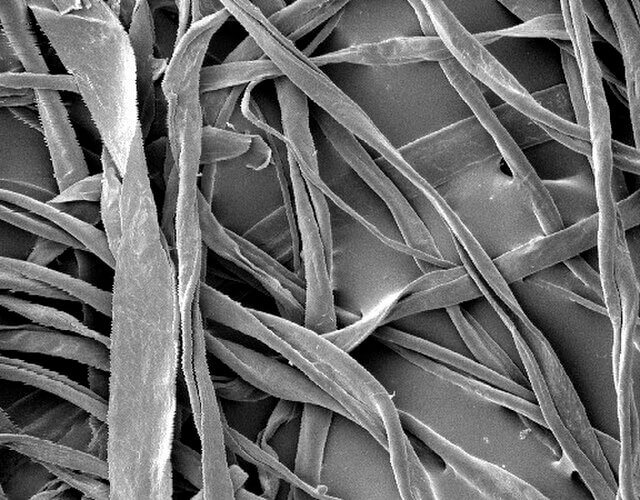

Cotton fibers under a scanning electron microscope. Photo by

Featheredtar.

Yarn geometry: How fibers become function

- Staple yarns: Short fibers spun together that create loft, insulation, and texture, including all natural fibers except silk are staple yarns

- Filament yarns: Continuous strands that are smoother, glossier, and often stronger

- Twist, ply, and blending tweak strength, stretch, drape, and surface feel, for example, blending cotton with polyester combines comfort and durability

Construction: The textile’s blueprint

How yarns are arranged defines stretch, stability, breathability, and feel:

- Wovens: Plain weave (stable, strong), twill (durable with better drape), satin (smooth but less abrasion-resistant)

- Knits: Weft knits (high stretch, soft drape) vs. warp knits (more stable, shape-retaining)

- Nonwovens: Spunbond (strong), meltblown (fine filtration), hydroentangled (cloth-like), needle-punched (thick, durable)

- Braids & meshes: Strong, flexible, allow controlled airflow or integration

- 3D structures: Built-in cushioning, ventilation, or impact absorption

Surface finishes and laminations

Performance can be layered on after construction, for example, water-repellence, antimicrobial treatments, flame resistance, thermal control, sensing elements, or laminates for barrier and comfort.

Underused textile superpowers

Outside of textile-led teams, many advantages go untapped:

- Passive moisture and heat control keeps users comfortable without batteries, fans, or added weight.

- Targeted stretch puts flexibility only where it’s needed, improving fit and reducing bulk.

- Friction mapping controls grip or slip at specific contact points to prevent sliding, chafing, or wear.

- Integrated sensing builds data collection into the material itself, avoiding separate components.

- Acoustic and vibration damping quiets mechanical noise and cushions vibration for comfort and usability.

- Biodegradable end-of-life supports sustainability goals without sacrificing function or durability.

These features can often be added with minimal cost or complexity — no radioactive spider bite required — but only if textiles are part of the conversation early enough.

Why teams miss this

Without early textile expertise, teams either oversimplify (“fabric is fabric”) or avoid it as “too complicated and unforgiving.” In reality, textiles can be one of the most adaptable systems in your product, if you bring in the right expert to design with them from the start.

Are you missing a textile opportunity?

Sometimes what makes or breaks a product isn’t a new feature or flashy technology — it’s the way the product feels, fits, and functions in real life. That’s where textiles often determine the user experience.

Common product missteps:

- Hard plastic against skin when a soft, breathable interface is more ideal.

- Over-engineering other materials to avoid a more elegant textile solution.

- Ignoring breathability, wearability, and long-term comfort.

- Defaulting to whatever the supplier offers instead of engineering the textile to match the product’s specific performance needs (abrasion resistance, UV stability, colorfastness, washability, and more).

What soft goods experts bring to the table:

- Strong understanding of use-case and user comfort, mapping real-world conditions like pressure points, moisture, heat, and movement to the right textile solution

- Ability to translate mechanical goals into material specs and patterned solutions

- Knowledge of sourcing, performance trade-offs, and manufacturability, finding materials that work while meeting cost, supply chain, and compliance needs

- Early-stage integration so textiles are part of the core product architecture, not an afterthought

Start asking these questions early in product development:

- Where is the body involved? Is there skin contact, joint movement, or variable pressure?

- What kind of contact, friction, or moisture is present? Is the surface static or sliding? Wet or dry?

- Could a textile solve the problem more elegantly? Would the right structure, finish, or fiber choice simplify the design and improve the user experience?

- Are we thinking about lifecycle from the start? Should the material last for years, biodegrade quickly, or be easily recyclable?

Conclusion: A call to re-see your materials

Textiles are more than just soft, they’re also strategic. They appear anywhere comfort meets complexity, bridging human needs with technical performance. They can stabilize a structure, manage heat and moisture, or create an interface that people actually want to use. (They may even walk your dog if you ask nicely.) They deserve a deliberate place in the product development process, alongside metals, plastics, and electronics.

Actual photo of textile walking your dog. Photo by Benjamin Lehman.

If you aren’t meticulously choosing your textiles, you’re probably using the wrong ones. From friction to breathability, from structural support to interface design, textiles influence the user experience in ways that often go unnoticed until something feels “off.” When you start specifying requirements and using them to make more intentional material choices, you open the door to better performance, simpler solutions, fewer redesigns, and happier end users.

This is just the start of a bigger conversation. Textiles hold far more potential than most teams realize, including design strategy, interplay of material capabilities, sustainability goals and smart integrations. The moment you stop seeing them as background elements and start seeing them as active design tools, you start finding opportunities you didn’t know existed. Likely ones that will take your product development to a whole new level. That’s when the real innovation begins.