The untapped potential of textiles

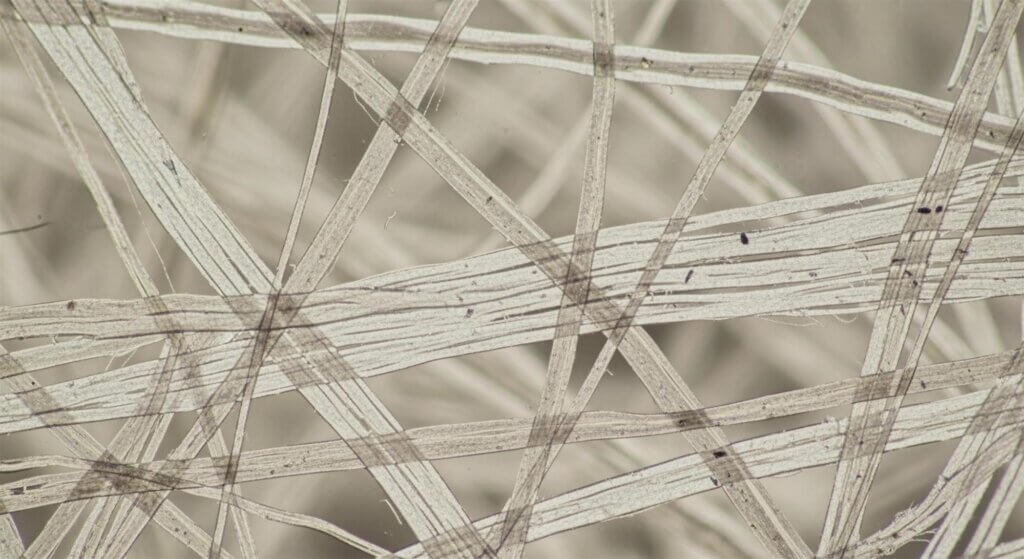

What if the difference between a good product and a great one was in the fabric? Oh wait — it is. Most teams don’t fully explore what textiles can do — structurally, thermally, chemically, or mechanically. This isn’t from lack of care; how can you explore something when you don’t know it exists? Textiles feel deceptively familiar — we see them everywhere, every day — yet many of their most influential properties work at a microscopic level, hidden from view. Because of that, teams often assume that picking a fiber content, a color, a look, and a feel is enough to make a successful product. But too often, those assumptions unravel.

Microscopic view of interwoven fibers. Source: Vecteezy

You might think your product is safe from such risks because you’re not designing technical gear or wearables. You’d be surprised how costly that assumption can be — and not just financially. Even the simplest products can become safety hazards when textile expertise isn’t part of the conversation. Take, for instance, the recent recall of children’s pajama sets that violated U.S. flammability standards; the In My Jammers line was pulled from the market in 2025 due to burn-hazard risk. The downfall wasn’t a pattern flaw or stitching error — it was a material oversight.

Textiles quietly decide whether a product is safe, durable, or comfortable — or whether it ends up recalled, returned, or buried in one-star reviews. Yet many development teams still treat fabric choice as an aesthetic decision or sourcing detail, not a core performance lever.

In this post, we unpack three classes of textile properties — chemical, mechanical, and physical — and show how smarter material decisions can unlock new levels of performance, comfort, and longevity in the products you’re already making. These are the hidden levers separating “good enough” from truly exceptional. It’s time textile expertise had a permanent seat at the development table.

What you can control with textiles

Textiles aren’t passive materials — they’re tunable systems. The same fabric can be made safer, cooler, softer, or stronger depending on what happens at the fiber, yarn, and finishing stages. Each decision quietly shapes how a product performs in the real world.

Before diving in: Many properties can be tuned at multiple levels — through fiber chemistry, yarn structure, fabric construction, or finishing. Flame resistance, wrinkle recovery, and moisture control can all originate from different points in that chain. What matters isn’t where the effect comes from, but how each decision supports the next.

Chemical & finishing properties

Some of a textile’s most powerful traits are invisible. Fiber chemistry and finishing treatments can make a material inherently flame resistant, antimicrobial, or UV-stable — or leave it vulnerable to failure. These chemical characteristics determine how a textile interacts with its environment over time: how easily a fabric wrinkles, whether moisture breeds bacteria, whether a protective garment self-extinguishes or melts when exposed to heat.

You can’t just pick any fabric for your hiking backpack and manifest that the color won’t immediately fade with sun exposure. No, dear reader, behind every vibrant backpack is a textile scientist who painstakingly chose the fiber content, dye type, and dye application techniques. Finishes can add repellency or softness, but they can also wash away if they’re not selected or applied properly. Chemical design decisions are where safety, hygiene, and longevity quietly begin.

Mechanical & structural properties

Mechanical properties describe how a textile behaves under force — strength, stretch, recovery, abrasion, tear resistance. They’re what make a seat belt reliable, a backpack strap comfortable, or a soft goods prototype durable enough to test repeatedly.

Many people think fabric is unruly and unpredictable, but that’s not the case. When textile experts aren’t consulted and mechanical performance is ignored, products fail in predictable ways: webbing elongates, seams split, or fabrics wear through in high-stress zones. Getting it right means balancing load-bearing capacity with flexibility, and knowing when the right answer is a stiffer weave, a yarn with a higher twist per inch, a more elastic knit, or a composite of both.

Fabric, refusing to follow the rules. Source: Vecteezy

Physical & sensory properties

Then there’s what the user actually feels. Weight, drape, density, air permeability, and thermal behavior all dictate comfort and perception of quality. Two garments can share the same fiber content but feel entirely different in motion.

Physical properties decide whether a jacket breathes or stifles, whether upholstery feels inviting or industrial. They’re the bridge between engineering and experience — the difference between a product that simply functions and one that people love to use.

Micro-level design choices

Even with the right material, performance isn’t guaranteed. How you build with that material — the yarn, the structure, the pattern, the finish — decides whether it meets its potential or falls flat. These are the choices that transform “good materials” into great products.

Yarn & fabric architecture

Two textiles can share the same fiber content and behave like entirely different species. Twist a yarn tighter and it gains strength and soil repellency but loses softness; add plies and you change bulk, stretch, and how it handles stress (although a good therapist helps as well). Swap a filament fiber for a staple one, and you change not just texture but also how the fabric manages moisture, abrasion, pilling, and static.

Then there’s structure. A woven fabric resists stretching but offers stability. A knit flexes easily and breathes better but may distort under load. Nonwovens can be customized for various properties, such as absorption, water repellency, sterility, or flame resistance. These decisions are the textile world’s version of structural engineering — the architecture that defines performance long before a seam is ever sewn.

Patterning & construction

Even the best fabric can’t save a bad pattern. Patterning governs how a product moves with the body, distributes pressure, and responds to real-world environments. Smart shaping allows range of motion without bulk; poor shaping creates bunching, restriction, or sag.

Comfort isn’t just softness — it’s how a garment or gear behaves in motion, whether it conforms to anatomy, resists snagging, or stays stable across temperature and humidity changes. The same logic applies to manufacturing. Efficient patterning minimizes waste and makes scaling feasible. Layering systems take it even further — pairing moisture-wicking liners with insulating mids or durable shells to create performance stacks that outperform any single fabric.

Dye methods & surface treatments

Color isn’t just branding. The dye type, method, and finishing process dictate colorfastness, compliance, and skin interaction. Solution dyeing locks pigment into the fiber itself for UV stability and long-lasting vibrancy, while piece dyeing trades durability for flexibility in color choice.

Finishes add another dimension — repellency, soil release, antimicrobial action, wrinkle resistance. Each adds performance, and each raises questions of longevity, sustainability, and compatibility with end use. The right finish enhances the product; the wrong one can compromise it before it ever reaches the user.

Why expertise matters

Textiles aren’t “just sewing.” They bridge chemistry, physics, ergonomics, and compliance — often all at once. Every property you tune in a fabric requires specialized knowledge, and most teams don’t know what to ask for, let alone how to evaluate the answers. That’s how products fail quietly: not through bad ideas, but through gaps in expertise.

A fabric that melts at the wrong temperature, a strap that stretches over time, a finish that washes out after a few cycles — these aren’t engineering oversights. They’re signs that textile decisions weren’t made by people who understand how fibers, finishes, and form interact over time.

Innovation in soft goods rarely comes from one genius material or tool. It comes from collaboration — from bringing together people who see different dimensions of the same fabric. The chemist knows how it behaves under heat and dye. The engineer knows how it bears load. The designer knows how it should feel. The pattern drafter knows how it moves on the body. When those perspectives converge early, products don’t just function — they excel.

This isn’t knowledge you can casually “pick up.” It comes from years of testing and pattern recognition — learning why one fabric thrives where another fails. The value of a varied textile team isn’t just precision; it’s foresight. Experts who understand the chemistry, physics, and human factors can spot problems before they appear. Some corners shouldn’t be cut: a soft goods product requires a soft goods expert.

Rethinking what makes products great

Textiles aren’t passive. They drive performance, comfort, and safety — the quiet framework beneath every successful product. They decide whether a design earns loyalty or ends up in a landfill.

Great ideas rarely fail because the concept is wrong. They fail because material decisions were made on autopilot — guided by cost or convenience instead of strategy. Assuming “fabric is fabric” is like judging an engine by its color.

When teams treat textiles as part of the performance system rather than an afterthought, everything improves: comfort, durability, manufacturability. Products stop fighting their materials and start working with them.

If you want lasting loyalty, you need the right expertise to make sure your product withstands time and use. Textiles are among the most versatile engineering tools available — but only if they’re understood. Textile experts don’t just choose fabrics; they translate goals into material reality.

If you haven’t deliberately explored your textile options, you’re likely leaving performance — and customer satisfaction — on the table. The difference between “good enough” and great may already be woven into your materials. You just need the right eyes to see it.

Could the greatness be hiding under this seam? Only one way to find out!

informal is a freelance collective for the most talented independent professionals in hardware and hardtech. Whether you’re looking for a single contractor, a full-time employee, or an entire team of professionals to work on everything from product development to go-to-market, informal has the perfect collection of people for the job.