Why hardware (scoping) is hard

Whether you’re familiar with the hardware world or not, starting a new project as a client can be daunting. Often, one of the first questions I get asked is “How much will this cost?” This is quickly followed by “How long will this take?” And my answer is always “It depends.”

Today, I’m breaking down why it’s difficult to scope and quote a hardware project, and how informal is working to make these estimates accurate.

Custom versus novel

Each project we work on is unique, which means that the cost and time for each is vastly different. If you’re building an enclosure for a Raspberry Pi, we know how it should function and what’s required to make it work. This type of project is custom — our client wants us to take something that exists and make it to their specifications.

Once we get into more complex and interrelated features, our ability to accurately scope and quote gets a little muddier. These are novel projects. They’re full of dependencies and unpredictability. Since we’re essentially designing something from the ground up, we don’t always know how different elements will play together.

Regardless of the type of project we’re working on, each variable that is altered or added creates a ripple effect within the project. Each feature must be tested, designed, and integrated into the larger system. Often, the complexities are multiplied with each new feature. For example, how will adding Bluetooth impact the battery life, size, or design of the object? All of these factors might need to be revisited or modified and tested to accommodate a new feature.

The revision process

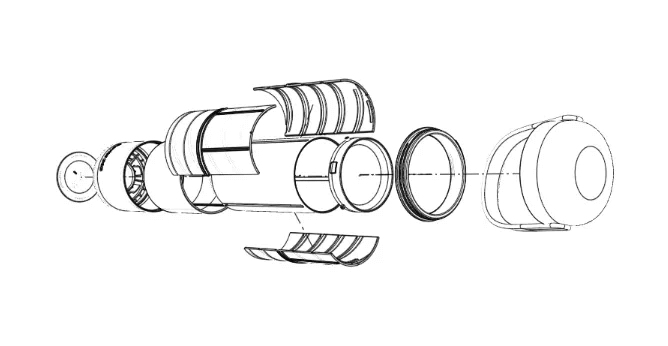

Beyond project complexity, we also have to take into account the revision process. The first prototype that we build is important because it lets us know if the concept will work, and it’s actually pretty easy for us to predict the scope and quote since it often uses “off-the-shelf” parts (which are normally easy to source). We may use a consumer-level developer board, standard sensors, and a prefabricated case to get the first version. And tada — you have a thing! But it isn’t optimized for performance or cost, and needs to be designed to be manufactured, otherwise it’ll be too bulky and too expensive to market.

As we start to nail down what the final design will look like and feel like, there’s a good chance that we’ll need to design custom parts. Again, each custom part must be tested alone, as well as within the whole product. This often requires a few rounds of iterations. Best case scenario, it takes just one or two iterations to get the product just right. But as the complexity goes up, it can take multiple rounds to get exactly what our client imagined.

As well, you may learn more about your own product or idea as you see it come to life and you may notice things that need to be changed. Keep in mind that each round of iterations likely involves multiple engineers and designers. This is why it becomes hard to estimate hours and effort ahead of time.

A few examples

Let’s compare three informal projects:

Burrito Pop, a personalized burrito holder, is a relatively simple design, but it’s completely novel in its use. Multiple rounds of iterations were needed to make sure the twisting mechanism worked smoothly and repeatably while still ensuring it was manufacturable.

Lodge Outdoor solar-powered speakers is a great example of the ripple effect we mentioned earlier. The design called for solar panels, as well as waterproof electronics, all while providing high-end audio quality. Many revisions were spent finding the sweet spot of performance, cost, and manufacturability.

Lastly, Neurosity makes a brain-monitoring headset. We worked with them to take their 3D-printed prototype and redesign the product to drastically reduce the cost to manufacture, the time it takes to assemble, and improve on the product design and features.

How can we make it easier?

informal has been quoting and working on projects for years now, and we have a bank of knowledge to pull from. We leverage the data on thousands of hours of previous projects in order to get a feel for how long each section of a new project may take. Using this, we can anticipate the number of revisions needed, and we can incorporate iterations into our estimates.

We also give clients the tools to understand and communicate the depth of their project so that we can best serve them through discussing what the client imagines, and telling them what’s possible within their budget of both time and money. We want to know what the client’s expectations are before we jump in. The more that we know ahead of time, the better our estimate. The farther out a forecast, or the more ambiguous a project, the less accurate a quote will be.

Even though projects can be hard to scope and quote, I still get excited whenever a client brings a new idea to the table. So, if you’ve got a product that you’d love to see made, tell me about it! But, if you ask how much it’ll cost or how long it’ll take, just be ready for the answer to start with, “It depends.” Don’t worry — we’ll follow up with how we can get you where you need to go.