Crowdfunding Red Pitaya: Lessons from building hardware in public

I met Nate Padgett, cofounder of informal, at the 5th San Diego Hardware Meetup in North County. The focus that evening was “Optimizing Hardware for Manufacturing,” a theme that resonated strongly with me as an engineer. Later, I subscribed to informal’s blog. A few months ago, I came across Sam Holland’s excellent two-part series on crowdfunding, The Crowdfunding Compass.

As cofounder of Red Pitaya, which started life as a successful Kickstarter project, I felt compelled to share our experience — not as a polished success story, but as a set of engineering and go-to-market lessons, told with honesty.

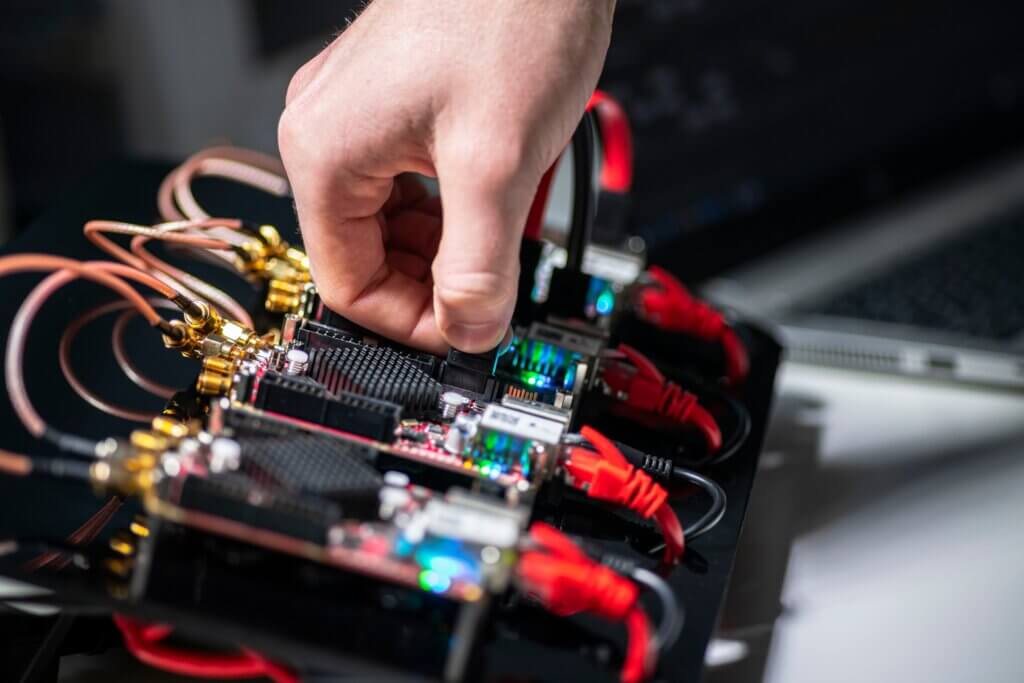

The the Red Pitaya STEMlab 125-14 X-Channel System

The campaign in numbers

- Title: Red Pitaya: Open Instruments for Everyone

- Subtitle: Technologies yesterday available only to research labs and industry turn your iPhone, tablet, or PC into an amazing instrument

- Campaign dates: July 22 – September 20, 2013 (60 days)

- Backers: 826

- Total pledged: $256,125

- Updates posted: 34 (between July 2013 and April 2014)

- Comments: 219 on Kickstarter page

- Final update: April 2, 2014 — nearly 7 months after the campaign ended

The fact that we kept posting updates for half a year beyond the campaign shows what Kickstarter really demands: transparency, humility, and the willingness to work through problems in public.

Where Red Pitaya came from

Red Pitaya didn’t begin in a garage. It began as a bold experiment inside Instrumentation Technologies, the company I founded in Slovenia in 1998 to build high-performance instrumentation for particle accelerators. After years working on particle accelerators in Italy and the USA, I became fascinated with hardware reconfigurability and FPGAs, even publishing an article in 2002 titled “Reconfigurable Instrumentation Technologies, Architectures and Trends.” My vision was to free radio-based instruments from the fixed limits of their hardware.

In late 2012, I decided it was time to take this vision beyond particle accelerators. I launched Project 913, a challenge to create a completely new product in just nine months. I gathered a small, passionate team: myself, Rok Ursic, RF engineer and entrepreneur; Crt Valentincic, embedded software engineer (today Red Pitaya’s CTO); Borut Baricevic, RF engineer and product manager (still at I-Tech today); and Ales Bardorfer, FPGA/software engineer (also still with I-Tech). Together, in a room covered with whiteboards, we began shaping what would become Red Pitaya.

Around that time, we drew inspiration from Brad Feld’s talk at the MAKE Hardware Innovation Workshop, where the renowned entrepreneur and venture capitalist spoke about the power of open source, the maker movement, and Kickstarter. His message — that users could once again design and fund the tools they truly cared about — resonated deeply with us.

That spirit defined Red Pitaya from the very beginning: reconfigurable hardware powered by FPGAs, built on open-source principles, and created for a global community of makers, innovators, and engineers.

Mapping our journey to the 8 compass steps

Sam Holland’s Crowdfunding Compass outlines eight steps. Here’s how Red Pitaya’s campaign looked through that lens.

Step 1: Concept design and specs

Sam emphasizes clarity of product, cost, timeline, and labor.

For us, Red Pitaya was a technology push. At I-Tech we had learned to use FPGAs in particle accelerator systems — a bet that paid off and differentiated us. With Red Pitaya, we wanted to bring that same power to a wider audience.

The board was designed as a software-defined measurement platform. One small FPGA-based board could act as an oscilloscope, spectrum analyzer, signal generator, or closed-loop controller.

“As engineers, we assumed the campaign would behave logically — like a circuit. Instead, we saw bursts of acceleration, followed by stagnation. That taught me that market psychology matters as much as specifications. For us, that was a strange realization,” explained Borut Baricevic.

The specs were solid. The challenge was telling the story in a way that non-accelerator physicists could understand and get excited about.

Step 2: Landing page and pre-launch testing

Sam recommends building an audience and testing messaging before launch.

We built around 10 prototypes before the campaign. Structured user testing came later. In many ways, Kickstarter was our market test. The 826 backers were proof that demand existed.

“The engineering team was ready. But success wasn’t just about engineering. Storytelling mattered. We could’ve sharpened positioning earlier, tested audiences more aggressively, and used momentum to reach industrial niches while the buzz was high,” reflected Edina Mulec, Creative Director, Marketing & PR at Red Pitaya.

Looking back, we didn’t fully appreciate the storytelling dimension until after launch. The open-source angle attracted makers, but our future markets — photonics labs, quantum researchers, industrial R&D teams — weren’t our early focus.

Step 3: Preparing the campaign

We chose a $50,000 goal. Why? It felt achievable but not trivial. The truth is, Red Pitaya had backup: Instrumentation Technologies. But we didn’t want to depend on that.

We ran the campaign for 60 days. That gave us time to gather momentum — but also tested our nerves.

“From a logistics perspective, it was crazy but unforgettable. We shipped 1,000 boards around the world. Everything went smoothly — except when Australian customs stopped a shipment because they thought Red Pitaya was fruit. The biggest lesson? Single-source components are a risk. I’d diversify earlier if I could do it again,” explained Mateja Lampe Rupnik, CEO of Red Pitaya.

Our credibility came from I-Tech’s experience: The cofounders had 40 years of combined expertise in RF, FPGA, and supply chain. Still, nothing prepared us for the roller coaster of public accountability.

Step 4: Launch and ongoing support during the campaign

The campaign went live on July 22, 2013. The first hours were exhilarating. Watching the funding bar climb became an addiction.

But what sustained the campaign wasn’t the thrill of pledges. It was a dialogue with backers. We responded to comments, posted 34 updates, and continued until April 2014.

“For me, the campaign was a milestone. Without it, Red Pitaya wouldn’t have had such a strong start. If I could go back, I’d engage the community even earlier and with more targeted content,” reflected Črt Valentinčič CTO of Red Pitaya.

In the early days, every bit of outside validation mattered. We weren’t just building hardware. We were trying to prove that a tiny team with a bold vision could change how engineers work. That’s why the first press coverage was such a turning point.

In 2013, TechCrunch surprised us with the headline: “Red Pitaya Lets You Measure All the Things.” Soon after, EE Times picked up the story with “T&M Turns to Open Source, Kickstarter.” Later that year, while visiting friends in Newport News, Virginia — people I knew from my time working at the particle accelerator there — I had the chance to connect with Adam Carlson who wrote articles for EE Times. He invited me to dinner at his home, where I shared our journey in detail, the setbacks, the breakthroughs, and the passion driving our campaign. A few weeks later, he published “Red Pitaya Becomes a Kickstarter Success Story” in EE Times. By 2014, DesignSpark added their own take: “Red Pitaya Bears Fruit and It Tastes Good.”

These articles weren’t just flattering headlines. They showed engineers outside our Kickstarter community that Red Pitaya was more than a project, it was becoming a movement. And then came a moment of real pride: Frost & Sullivan recognized Red Pitaya with the 2014 Global Electronic Test & Measurement Tools New Product Innovation Award, officially announced on January 15, 2015. For us, that wasn’t just an award; it was a signal that our vision had earned a place in the wider world of test and measurement.

Step 5: Engineering and design after funding

Kickstarter is the start, not the finish. Once funded, the real work began.

We went through constant design iterations: works-like prototypes, beta testing, integration. Stress levels were high. But shipping the first boards created something invaluable: unexpected use cases.

Researchers adapted Red Pitaya for applications we hadn’t envisioned, for example:

NASA’s Jet Propulsion Laboratory (JPL) selected a specially modified Red Pitaya STEMlab 125-14 board as the data acquisition/control board in its Space Atmosphere Monitor, which monitors air quality on the International Space Station. Red Pitaya enabled Long Path Technologies to scale their methane-monitoring laser networks from lab prototypes to robust, cost-effective, field-deployed systems with real-time signal acquisition and processing. In 2019, we proudly stepped into the quantum world by partnering with Xanadu, a visionary in the pursuit of accessible quantum computing where they used Red Pitaya to squeeze light from a nanophotonic molecule.

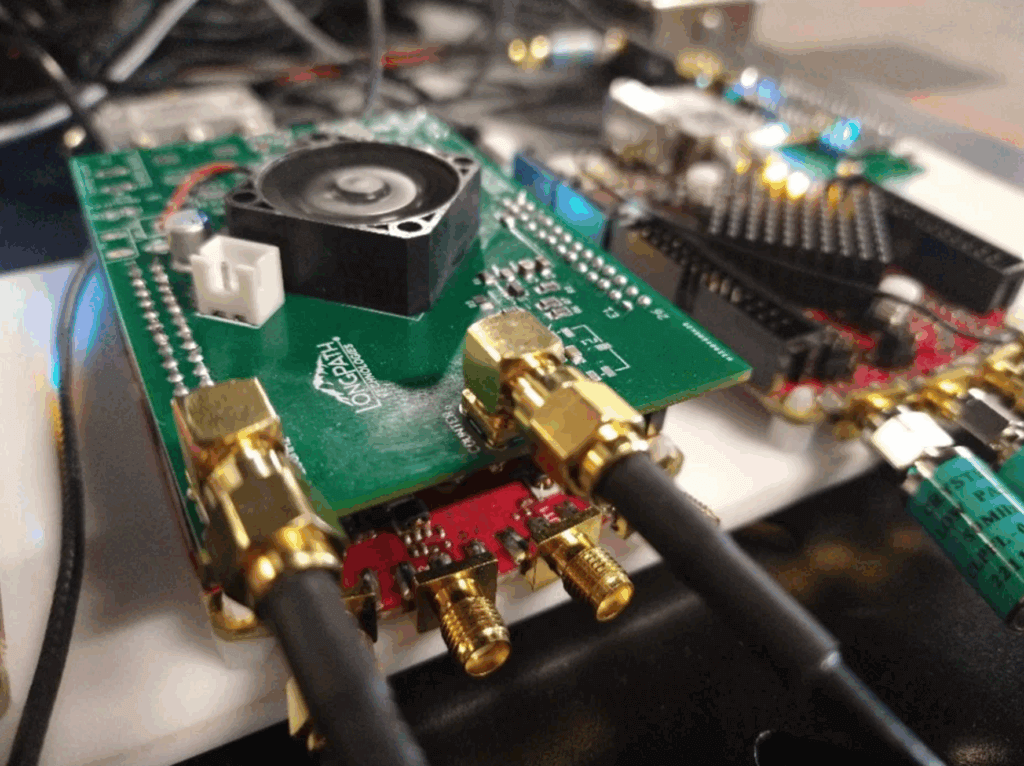

Laser monitoring of methane emissions with Red Pitaya

Step 6: Manufacturing partners

When it came to manufacturing, we were fortunate. Through Instrumentation Technologies, we had access to a reliable production network, and L-Tek Elektronika became a key partner in handling the production and logistics of our first Kickstarter batch. Their responsiveness, flexibility, and commitment gave us a far smoother path to market than many hardware startups experience.

In parallel, we built strong relationships with leading silicon providers.

“Despite the challenges, we had strong support from Xilinx and Analog Devices. Their early backing was crucial in enabling us to scale globally,” reflected Mateja Lampe Rupnik.

Hardware founders often underestimate how fragile supply chains can be. In hindsight, having these partnerships was one of our biggest advantages.

Step 7: Production ramp-up

By mid-2014, we moved from Kickstarter fulfillment into real distribution. RS Components and Allied Electronics became our first global distributors, which represented a big bust.

Certification was a major hurdle. Red Pitaya secured:

- CE Declaration of Conformity

- CB Test Certificates for EMC and Safety

- Compliance for RoHS, REACH, Conflict Minerals

These steps were invisible to most backers but vital for becoming a commercial product.

Step 8: Ongoing support and evolution

Crowdfunding doesn’t end when you ship.

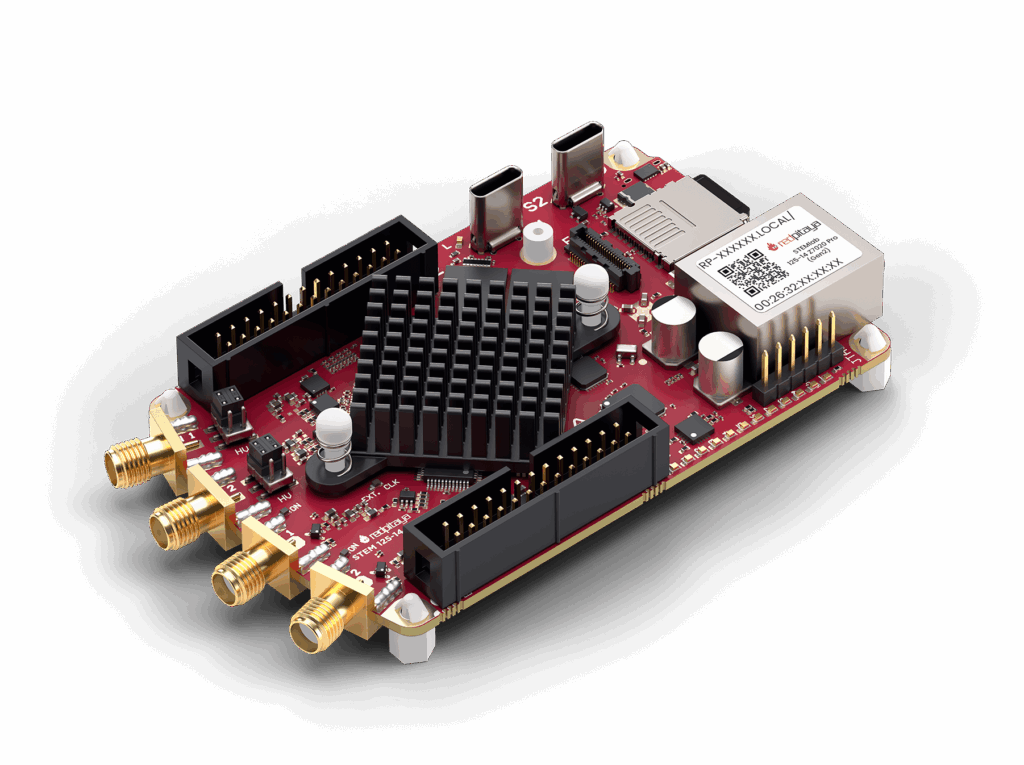

We continued engaging the community, learning from users, and iterating. Over time, Red Pitaya evolved into multiple variants, including a 250 MS/s version and, more recently, Red Pitaya Gen 2.

The Red Pitaya STEMlab 125-14 Gen 2

Today, more than 80% of our customers are in industry and education — in photonics, quantum, and test & measurement. NASA, Apple, MIT, and countless others use the platform.

“Kickstarter was great for makers and hobbyists. But if we had engaged industry and academia earlier, we could have transitioned faster into professional markets,” explained Nina Jerkic, Marketing Manager at Red Pitaya.

That transition was painful but necessary. It’s one reason I believe sharing these lessons matters — so other hardware founders can anticipate the pivot earlier.

Closing reflections

What did Kickstarter teach us?

- Team matters more than anything.

- Markets aren’t rational — psychology and story are as important as specs.

- Community trust is built by transparency.

- Adaptation is survival — from hobbyists to industrial users, we had to pivot.

- Open platforms plus customization create opportunities with leaders like NASA and Long Path Technologies.

For me, the campaign was never just about validation. It was a reminder that building hardware — especially through crowdfunding — means building in public. Every success, delay, and design decision was shared with hundreds of backers watching in real time. And in that environment, the real measure of success wasn’t just the money raised, but our ability to listen, adapt, and keep growing as engineers, as a team, and as human beings.

By sharing our story here, we hope to contribute back to the hardware community that supported us.

Do you need help with a crowdfunding project or something related to go-to-market? We have the experts you need to get the job done! Reach out using the link below to let us know about your needs and someone from our team will be in touch ASAP!