Designing a PAPR with Sara Pavis

This week in our project chat, Sara Pavis, one of our mechanical engineer members shared with us her process for designing an air purifying respirator (PAPR) for the average person.

Pavis explains these systems have evolved a huge amount before and after COVID-19, previously being used mostly in welding to and specialized medical cases. PAPR devices are forced air powered masks inside a sealed inclosure, the air is pushed throw a filter to the wearer, allowing an enclosed space to protect eyes, face, and air quality.

Sara says the reason most people don’t wear them is that they are intimidating, bulky, and a clear indicator that you are very serious about COVID-19. “Nobody ever wears them”, she says “but people ARE still looking for protection against COVID”. With new variants being more transmissible, Pavis wonders if form factor would influence people wearing a PAPR, and has been trying to think through what that might look like. “Masks should be more like seat belts, they should be seen as needed and but burdensome” she says. During the early pandemic, device such as 3D printed door openers and mask supports where extremely popular, while they seem to make things easier actually aren’t very effective — or are even counter effective, but people are buying them.

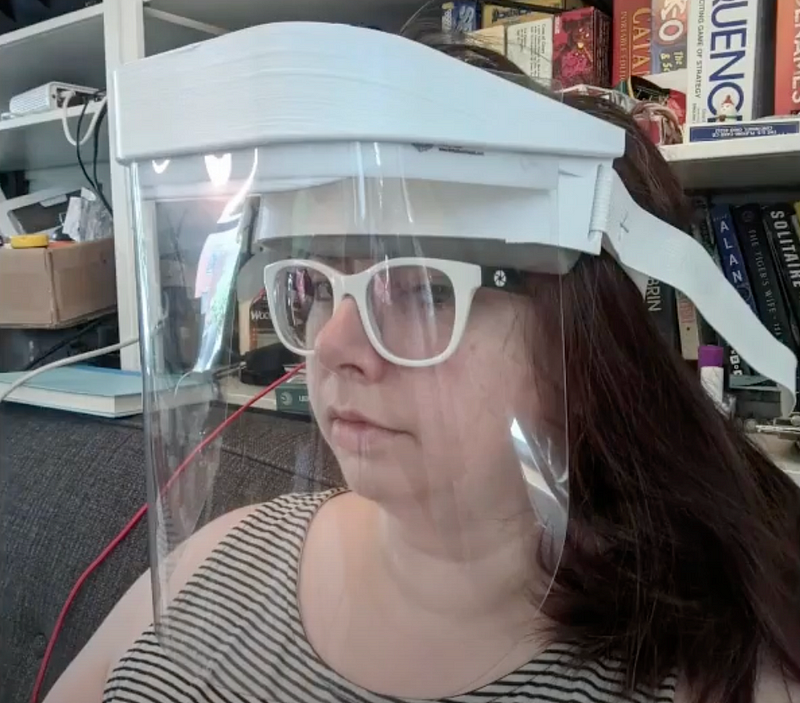

Sara theorized that a PAPR that would be easier to use might be less bulky, have more sides open, and an ability to modify your enclosure to fit the risk of an exposure in a particular situation. Having higher airflow would allow the enclosure to be more open, while still providing protection by overcoming any leaks and look more casual — like a hat!

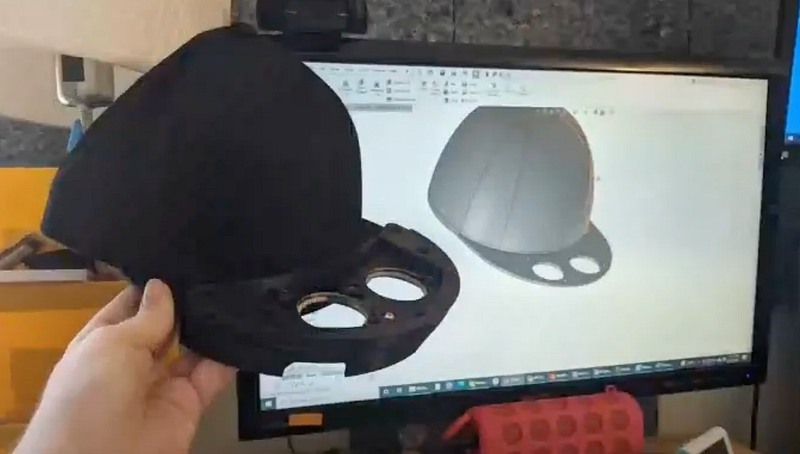

Sara created 2 prototypes, the first one uses blowers to force air through a surgical mask filter and over the face. This way, the wearer only breaths filtered air. Her second prototype integrates this model into a hat, for a more casual look.

Do you think the future of masks is in PAPRs? What would it take for you to wear one?